Services

Home Services Researches Metallurgy

TOMS Institute implements metallurgical studies of different types of ore and processing products, containing nonferrous metals (Au, Ag, Pt, Zn, Cu, Pb,Mo, Co. Nb, Ni etc.).

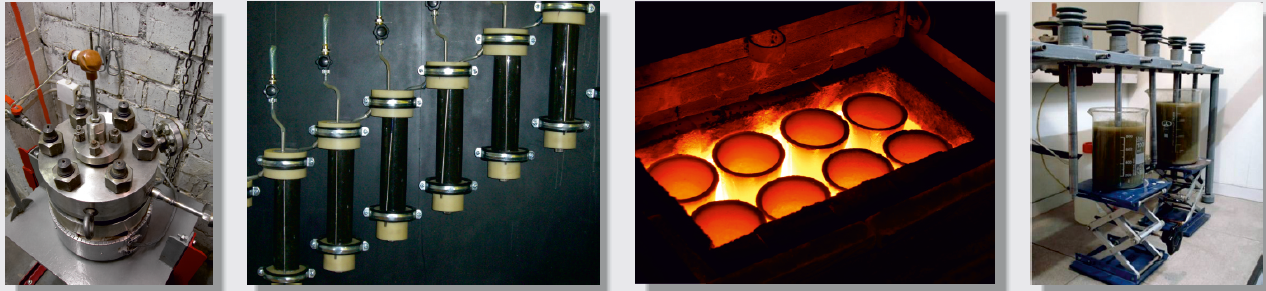

TOMS Institute metallurgy laboratory is fully equipped and uses advanced methods that allow performance of the following works:

- Leaching tests in standard conditions (bottle tests, etc);

- Intensive cyanidation tests on gold-containing products in ACACIA reactor:

- Tests to identify CIP process parameters (sorption isotherm, sorbent gotype, tanks etc.);

- Modeling of CIP (RIP) and CIL (RIL) processes, Pump Cell;

- Intensive leaching tests of Au, Ag concentrates under the influence of temperature and using special reagents;

- Heap leaching (physical and mechanical characteristics of ore and ore pellets, leaching under agitation conditions, in percolator and in columns of 6 meters high);

- Copper, zinc and other metals recovery from productive solutions (EW. SX-EW);

- Autoclave oxidation of any mineral products- gold containing ores and concentrates, sulphides, aluminum bearing products, zink fumes etc. (POX);

- Testing by means of modern hydrometallurgical processing technology of refractory concentrates: ultrafine grinding and mild oxidation in special reactors without temperature and pressure influence ore preparation for leaching, separation of refractory sulphides (Au, Ag, Cu, As, Fe ores). Research is carried out using automated pilot plant;

- Hydrometallurgical and pyrometallurgical tests for any type of minerals;

- Tests for metallurgical products and processing tails detoxification (cyanide destruction, arsenic detoxification etc.);

- Development of flowsheets for metallurgical treatment as well as recommendations for technology development report;

- Pyrometallurgical treatment of precious metal concentrates;

- Precious metals refining;

- Albion Process Testwork (specially designed Albion Process Leach Reactor, Au, Zn, Cu).

TOMS institute offers new technologies in this sphere:

- Cyanide containing flows detoxification, cyanide regeneration and nonferrous metal recovery from solution;

- Detoxification and disposal of arsenic bearing products;

- Detoxification and disposal of mercury bearing waste;

- MMS Cyanide Destruction Process CN-D.

TOMS institute suggested a way for copper sulphide products processing that is based on a combination of hydrometallurgical and flotation technology. This technique not only helps to increase copper recovery into final product, but also to significantly decrease the amount of concentrate (up to 3 times) that is subsequently fed to autoclave decomposition or even to completely eliminate this section.